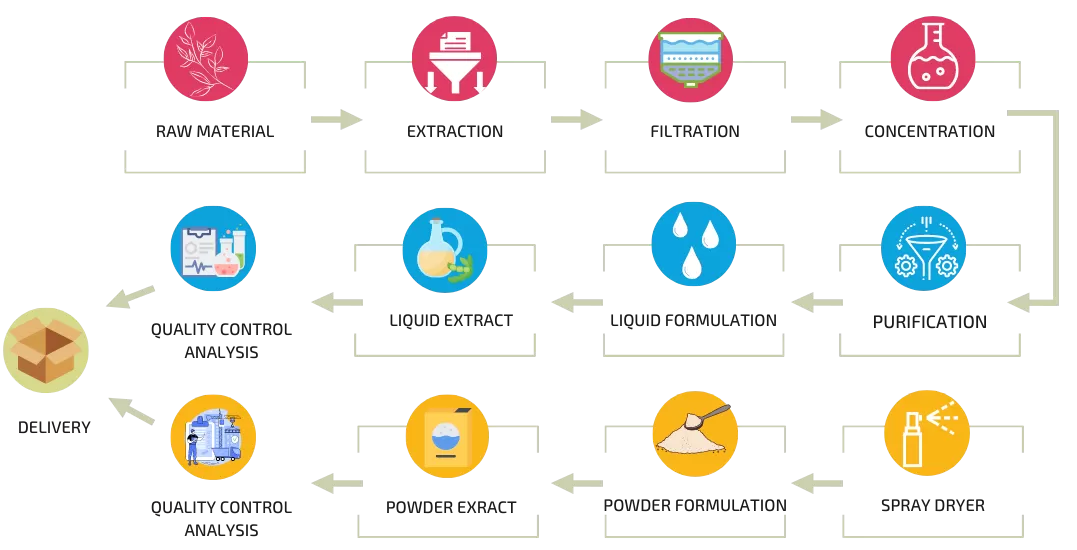

NPROC Botanical Extract Production Process - From Raw Material to Quality Control Analysis

Nproc's Journey

Production Steps

- I - Sourcing

- II - Reception

- III - Raw Material Analysis

- IV - Manufacturing

- V - Final Analysis and Finished Product Release

- VI - Warehouse and Traceability

- VII - Delivery To The Our Customers

Address

Bahçelievler Mah. 430 sok. No: 19 Torbalı / İZMİR / TÜRKİYE